Product overview

Adsorption concentration unit is a new generation of VOCs treatment equipment independently developed by Huashijie. It is a method that organically combines the adsorption concentration unit and the thermal oxidation unit. It is mainly aimed at the organic waste gas with large air volume and low concentration. After adsorption purification and desorption, it is converted into organic waste gas with small air volume and high concentration for thermal oxidation treatment, and the heat released by organic matter combustion is effectively utilized.

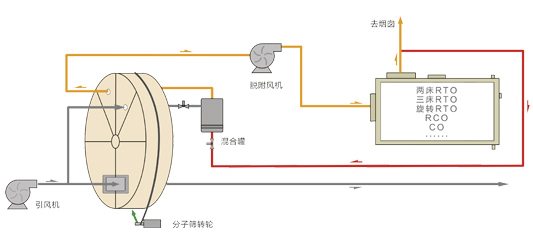

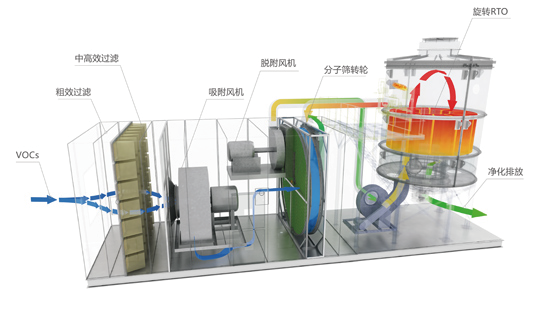

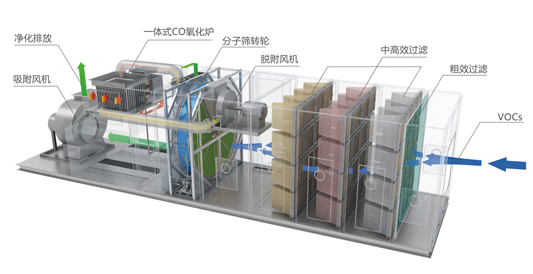

Process principle description

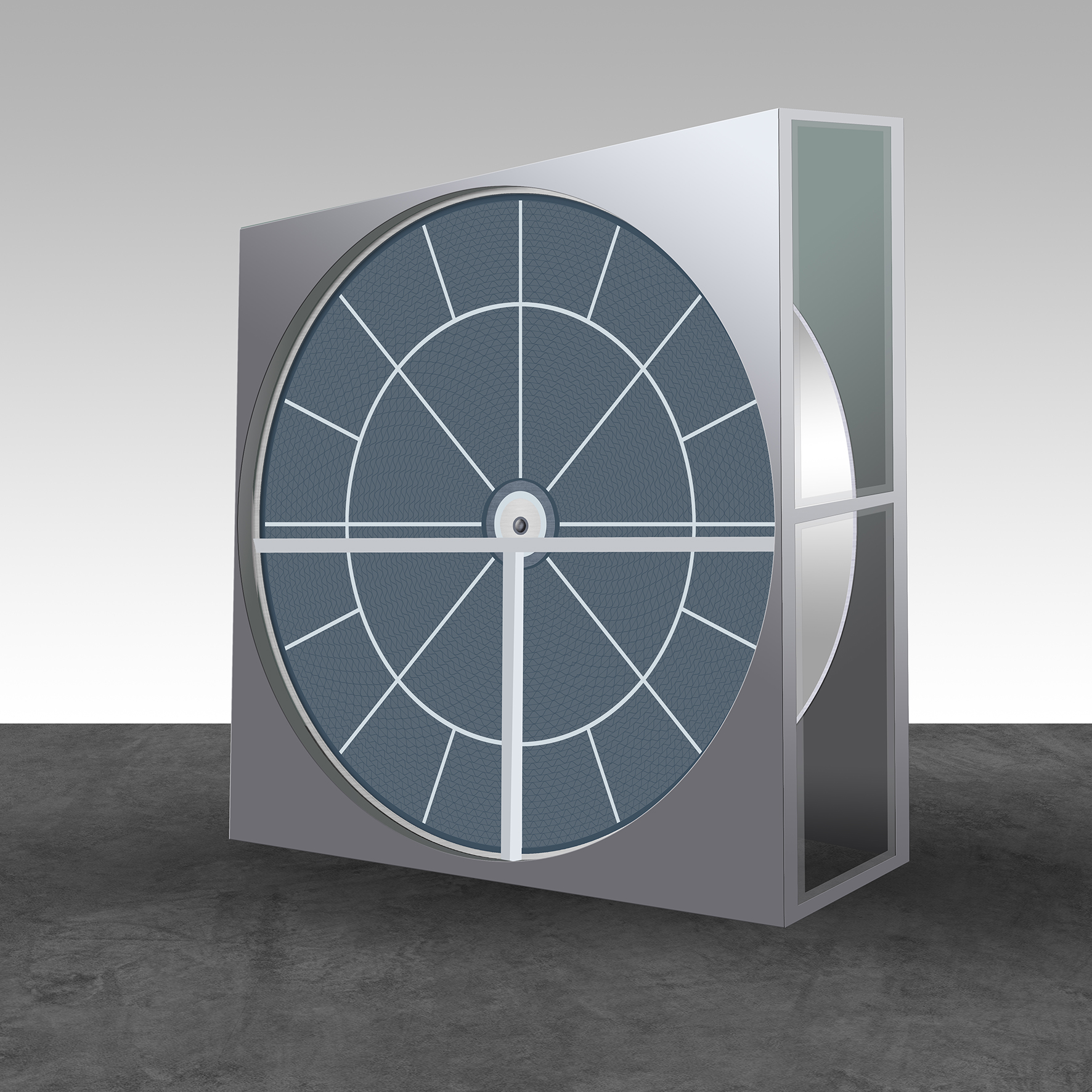

Process schematic diagram

Technological features

Characteristics of molecular sieve rotor + RTO combination process:

Oxidation temperature ~ 800 ℃

The heat transfer efficiency is more than 95% when the regenerative ceramic is used as the heat exchanger

The treatment efficiency is 90% - 99%

The floor area is relatively moderate

Maximum temperature resistance ~ 1000 ℃

Can deal with sulfur, halogen and other organic substances

Suitable for continuous operation

Characteristics of molecular sieve rotor + CO combination process:

Oxidation temperature ~ 300 ℃

Tube or plate type heat exchanger is used, and the heat exchange efficiency is about 65%

Treatment efficiency 90% - 99%

The floor area is relatively small

Maximum temperature resistance ~ 500 ℃

Cannot deal with sulfur, halogen and other organic substances

Suitable for intermittent operation

Application industry

Exhaust gas treatment of various painting workshops (automobile manufacturing, shipbuilding, bicycle manufacturing, aircraft manufacturing, metal products, etc.)

Exhaust gas treatment of various printing workshops (gravure printing, building decoration material printing, other printing processes)

Exhaust gas treatment of aluminum profile production and coating process

Exhaust gas treatment in the manufacturing process of various electronic products

Exhaust gas treatment in the manufacturing process of semiconductor integrated circuit and liquid crystal display (LCD)

Exhaust gas treatment of lithium ion battery manufacturing (electrode forming process, electrolyte filling process)

Exhaust gas treatment in the production process of resin, rubber, tire and other products

Exhaust gas treatment of volatile organic compounds from automobile repair shop and dry cleaning shop

Treatment of exhaust gas containing nitrogen, sulfur, chlorine and other impurities

- • VOCs adsorption and concentration treatment

- • Thermal oxidation/catalytic oxidation

- • Adsorption and recovery of high concentration VOCs

- • Biological treatment of odor VOCs

- • Industrial dust and oil mist filtration

- • Heat recovery

- • Dehumidification

- • Indoor purification

- • VOCs Online Monitoring Platform

Nationwide service line:400 0377 123

Nationwide service line:400 0377 123