Overall introduction of the equipment

The device is an integrated box type device integrating biological trickling filter and biological filter module, spray humidification system, fan, air duct, heating device, power distribution cabinet, frequency converter, electrical appliance, instrument and PLC automatic control system. Modular and standardized design, mass production, effective cost reduction, faster delivery.

Core advantage

| Independent core materials: huashijie's strong R & D team / ensures the core competitive advantage of products / all core materials have independent intellectual property rights and independent production |

| Modularization of non-standard equipment: standardized production, guaranteed product quality, standard parts, faster installation and replacement, modular production, more beautiful product design |

| Mass production of modular equipment: mass production, reduction of production cost / assembly line operation, improvement of production efficiency / automatic production line, guarantee of product quality |

| High quality project: fine construction / quality service / Systematic Guarantee |

technological process

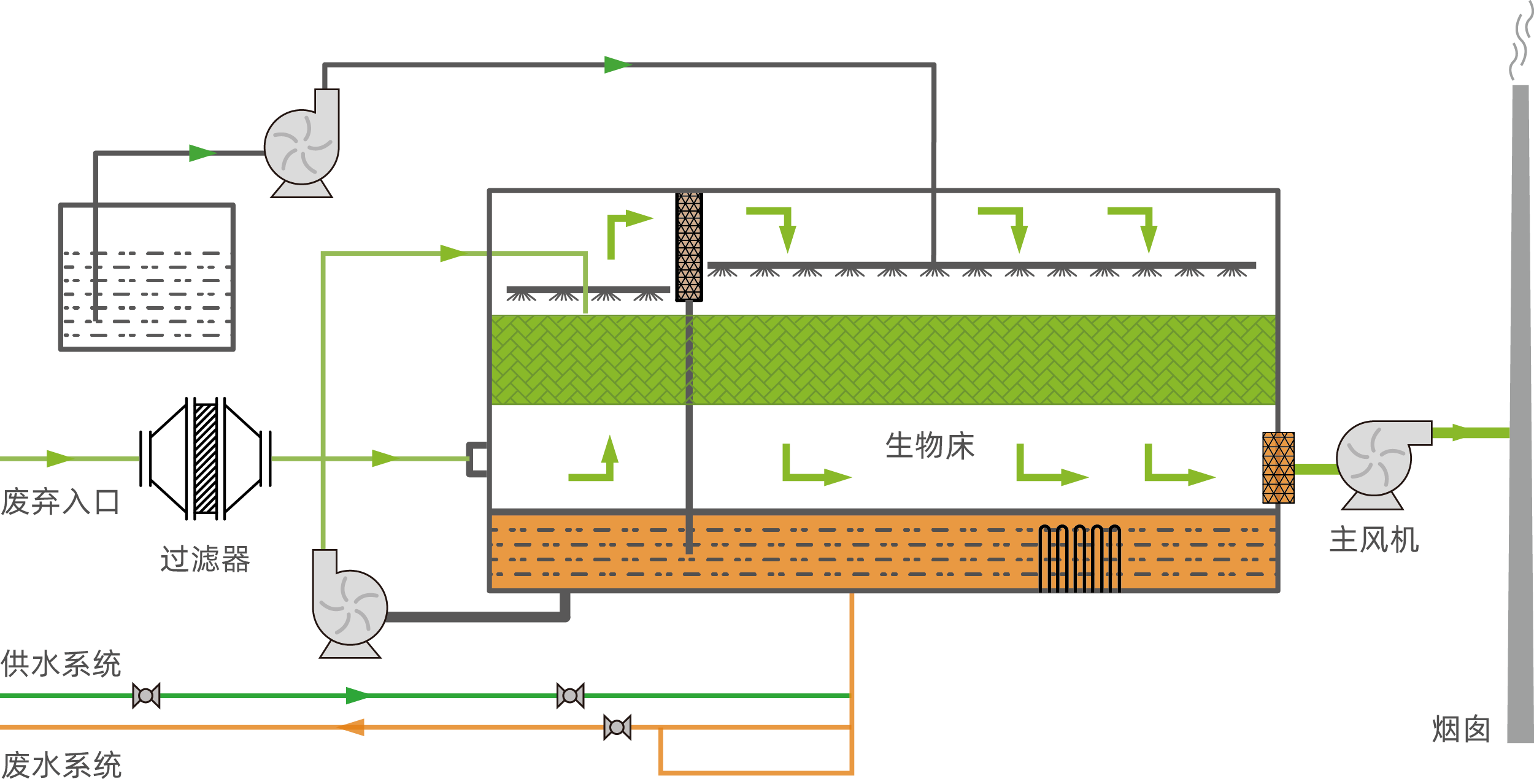

Huashijie biological treatment process is composed of biological trickling filtration and biological filtration. It is also called two-stage biological process. It can treat both soluble and insoluble pollutants. The rear fan is adopted, and the negative pressure inside the device works to reduce the emission of waste gas to the environment as much as possible.

The process flow of two-stage biological waste gas treatment is as follows:

After the waste gas enters the device, the biotrickling section in the device and the spray liquid exchange gas and liquid reversely on the packing surface. Most of the soluble pollutants are transferred from the gas phase to the water phase, and the spray liquid circulates. The pollutants in the water phase are used by the microorganisms attached to the packing surface, and are degraded into harmless substances through microbial life activities.

The insoluble pollutants enter the biofilter section with the waste gas, and are captured by the biofilm attached to the surface of the filler, and are digested as nutrients to further realize the harmless treatment of pollutants. The waste liquid produced by the microbial system can be discharged into the sewage system of the plant or the sewage treatment plant due to the absence of harmful substances and B / C ≥ 0.3.

working principle

The pollution substances in the waste gas components are transformed into carbon dioxide, water, polysaccharides, protein organic substances and microbial cell components, inorganic salts and other low harmful or harmless substances by using the life metabolism activities of microorganisms, so as to realize the effective treatment of the components of waste gas pollutants. The process of the transformation of pollutants in micro objects is shown in the following figure:

- • VOCs adsorption and concentration treatment

- • Thermal oxidation/catalytic oxidation

- • Adsorption and recovery of high concentration VOCs

- • Biological treatment of odor VOCs

- • Industrial dust and oil mist filtration

- • Heat recovery

- • Dehumidification

- • Indoor purification

- • VOCs Online Monitoring Platform

Nationwide service line:400 0377 123

Nationwide service line:400 0377 123