Industry summary

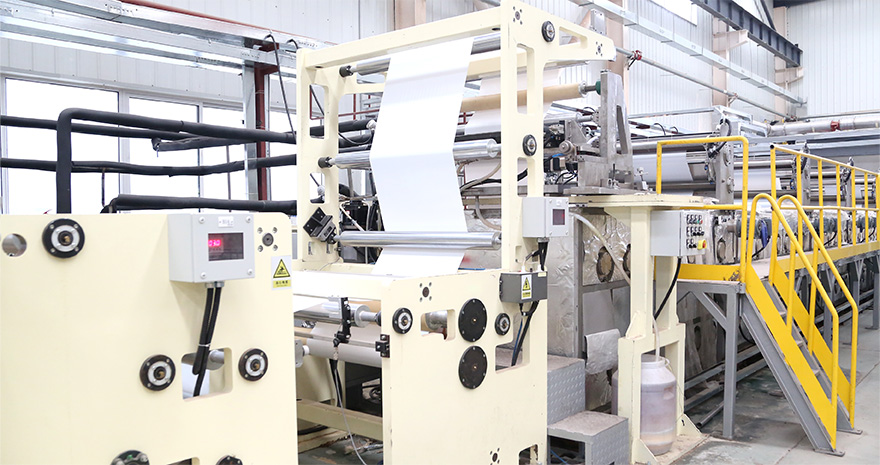

New material is a key industry in the 21st century, and composite is an important trend in the development of new material technology. Ultra high strength polyethylene, UHMWPE, lithium battery separator and other industries use white oil as solvent, dichloromethane, toluene, hydrocarbon cleaning agent as extractant, and produce high concentration of VOCs in the process of extraction and drying. As an early environmental protection enterprise in the new material industry in China, Huashijie has accumulated a large number of well-known customers and rich design experience, and can provide a complete set of solutions from new material production to environmental protection process.

Industry solutions

For new materials such as lithium battery separator and ultra-high strength polyethylene fiber, the exhaust gas mainly comes from extraction and drying, with small air volume, high concentration and less dust. The method of adsorption recovery + liquid separation is preferred. Huashijie specially develops high-efficiency activated carbon fiber for new material industry, with large adsorption capacity, up to standard export emission, up to standard recovery solvent purity and chroma, and short investment return period.

Case 1:Huashijie adsorption and recovery equipment is used in many branches of a well-known battery separator enterprise

Case 2:A well-known special fiber enterprise adopts Huashijie adsorption and recovery equipment for multi-phase construction

Molecular sieve runner + thermal oxidation • Regenerative thermal oxidation RTO • Adsorption recovery

Customer service

- • VOCs adsorption and concentration treatment

- • Thermal oxidation/catalytic oxidation

- • Adsorption and recovery of high concentration VOCs

- • Biological treatment of odor VOCs

- • Industrial dust and oil mist filtration

- • Heat recovery

- • Dehumidification

- • Indoor purification

- • VOCs Online Monitoring Platform

Nationwide service line:400 0377 123

Nationwide service line:400 0377 123