Product overview

Adsorption concentration unit is a new generation of VOCs treatment equipment independently developed by Huashijie. It is a method that organically combines the adsorption concentration unit and the thermal oxidation unit. It is mainly aimed at the organic waste gas with large air volume and low concentration. After adsorption purification and desorption, it is converted into organic waste gas with small air volume and high concentration for thermal oxidation treatment, and the heat released by organic matter combustion is effectively utilized.

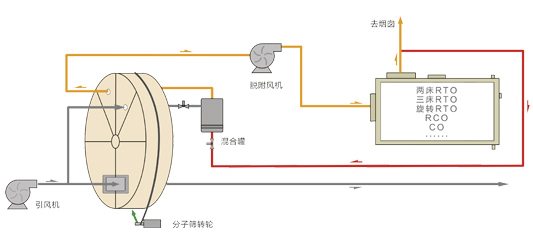

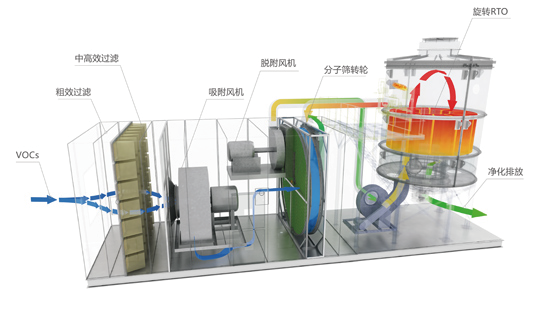

Process principle description

Process schematic diagram

Technological features

Characteristics of molecular sieve rotor + RTO combination process:

Oxidation temperature ~ 800 ℃

The heat transfer efficiency is more than 95% when the regenerative ceramic is used as the heat exchanger

The treatment efficiency is 90% - 99%

The floor area is relatively moderate

Maximum temperature resistance ~ 1000 ℃

Can deal with sulfur, halogen and other organic substances

Suitable for continuous operation

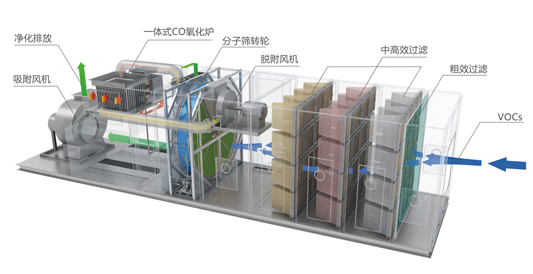

Characteristics of molecular sieve rotor + CO combination process:

Oxidation temperature ~ 300 ℃

Tube or plate type heat exchanger is used, and the heat exchange efficiency is about 65%

Treatment efficiency 90% - 99%

The floor area is relatively small

Maximum temperature resistance ~ 500 ℃

Cannot deal with sulfur, halogen and other organic substances

Suitable for intermittent operation

Application industry

Exhaust gas treatment of various painting workshops (automobile manufacturing, shipbuilding, bicycle manufacturing, aircraft manufacturing, metal products, etc.)

Exhaust gas treatment of various printing workshops (gravure printing, building decoration material printing, other printing processes)

Exhaust gas treatment of aluminum profile production and coating process

Exhaust gas treatment in the manufacturing process of various electronic products

Exhaust gas treatment in the manufacturing process of semiconductor integrated circuit and liquid crystal display (LCD)

Exhaust gas treatment of lithium ion battery manufacturing (electrode forming process, electrolyte filling process)

Exhaust gas treatment in the production process of resin, rubber, tire and other products

Exhaust gas treatment of volatile organic compounds from automobile repair shop and dry cleaning shop

Treatment of exhaust gas containing nitrogen, sulfur, chlorine and other impurities

Product overview

Honeycomb activated carbon adsorption treatment of organic waste gas is to make use of the characteristic of activated carbon micropores that can absorb organic substances to absorb the organic waste gas of large volume low concentration in the organic solvent to activated carbon and concentrated it, the clean gas directly discharged after adsorption purification. Catalytic combustion desorption is to heat the adsorbed organic solvent in the activated carbon to the boiling point by using the hot air generated from the decomposition of organic waste gas in catalytic combustion, and then introduce the concentrated high concentration waste gas into the catalytic combustion device for thermal oxidation reaction and discharge after reaching the standard.

Air volume: 5000-100000 nm 3 /h

Components: organic waste gas

Concentration: ≤ 1000mg/nm 3

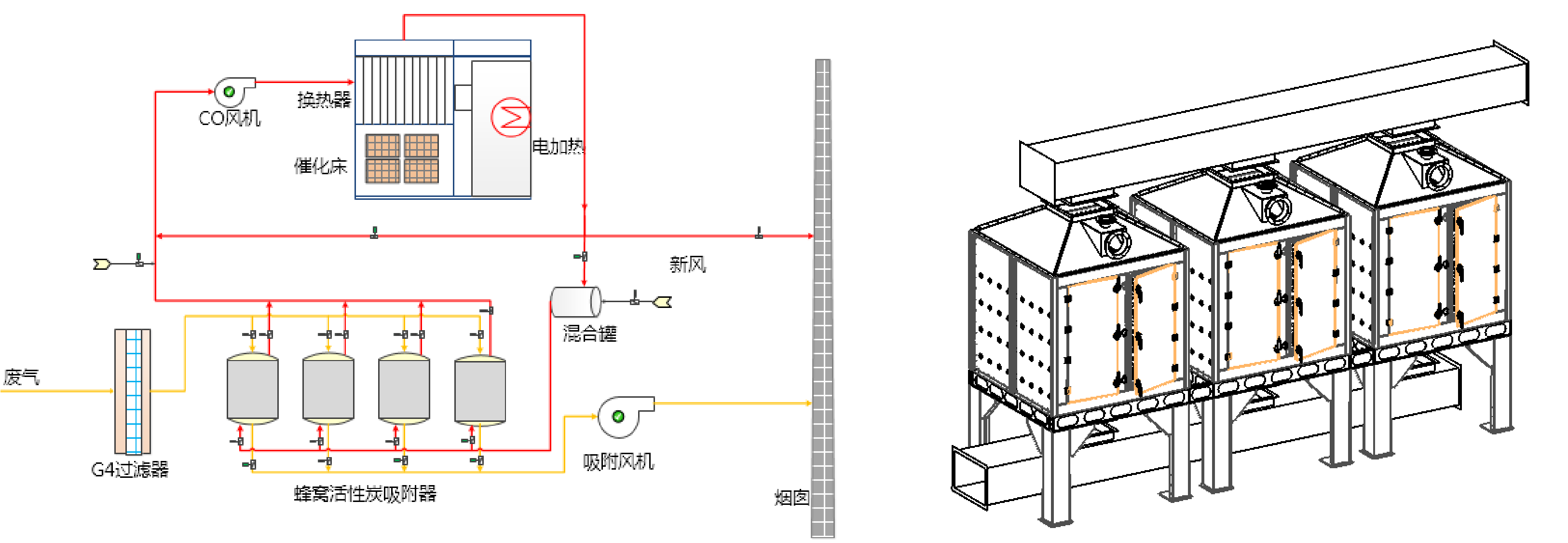

Process principle description

Honeycomb activated carbon adsorption bed

The principle of honeycomb activated carbon adsorption catalytic combustion desorption is to make use of the strong adsorption characteristic of activated carbon and low boiling point of organic solvent, first use activated carbon adsorption, when the activated carbon adsorption reaches saturation, start the catalytic combustion device, use electric heating to produce a small amount of hot air about 60 ~ 120 ℃ to heat the saturated activated carbon, so that the organic solvent in the activated carbon reaches boiling point to desorption After the thermal oxidation reaction, the high concentration waste gas entering the catalytic combustion device becomes clean and harmless gas and is directly discharged, or enters the heat exchange device, and the high concentration waste gas desorbed from the activated carbon is preheated in the heat exchange device to achieve the goal It is close to the temperature of thermal oxidation, and then the thermal oxidation reaction is carried out in the catalytic combustion device. In this way, only a small amount of heat is provided by the electric heater to reach the thermal oxidation temperature, which reduces the power of the electric heater of the catalytic combustion device, makes the catalytic combustion device and the desorption process of activated carbon achieve low power operation, and reduces the operation cost.

Technological features

1.High adsorption efficiency and strong adsorption capacity

Honeycomb activated carbon has larger specific surface area, higher adsorption efficiency and stronger adsorption capacity than granular carbon and columnar carbon.

2.Wide range of application

Honeycomb activated carbon is suitable for sulfur dioxide, nitrogen oxides, nitrogen oxides, aromatic compounds and other major air pollutants, as well as various toxic and harmful gases, volatile VOC gases and organic solvents emitted by industrial and mining enterprises.

3.Small area, simple maintenance and high efficiency

Honeycomb activated carbon equipment has compact structure, small floor area, simple and convenient maintenance and management, low operation cost, and the purification rate of organic waste gas after adsorption treatment by honeycomb activated carbon method is more than 90%.

Product features and advantages

| Advanced design concept: system integration, standardized / modular design makes the construction period more flexible / turnkey project, so that customers can leave the project to experts. |

| Scientific and rigorous design means: Fluent software is used for numerical simulation / optimization of the internal flow field distribution of activated carbon bed equipment. |

| Excellent and efficient operation performance: treatment efficiency above 90%. |

| Reliable safety performance: multiple monitoring and early warning / multiple safety interlock to ensure efficient and safe operation. |

| Convenient and fast network interaction: remote control, real-time online monitoring. |

| Simple and efficient operation performance: modular management, programmed control, automatic operation / simple and efficient, convenient and fast maintenance. |

| Appearance of the equipment: the activated carbon bed adopts sheet metal structure design as a whole, neat and beautifully presented with few welding parts. |

Application industry

Suitable for coating, spraying, printing, chemical industry and other industries.

Air volume: 5000 ~ 100000 Nm3 / h

Component: organic waste gas

Concentration: ≤ 1000mg / Nm3

- • VOCs adsorption and concentration treatment

- • Thermal oxidation/catalytic oxidation

- • Adsorption and recovery of high concentration VOCs

- • Biological treatment of odor VOCs

- • Industrial dust and oil mist filtration

- • Heat recovery

- • Dehumidification

- • Indoor purification

- • VOCs Online Monitoring Platform

Nationwide service line:400 0377 123

Nationwide service line:400 0377 123