HSJ Fixed Source VOCs Online Monitoring Equipment

Hsj VOCs on-line monitoring system is a product of huashijie Environmental Protection Technology Co., Ltd. The product has stable and reliable performance, high degree of automation and high detection sensitivity.

在线监测CCEP认证

Online monitoring CCEP certification

System advantages

Brand advantage: VOCs environmental protection industry professional brand, fixed source online monitoring / monitoring system perfectly combined with huashijie treatment equipment / compatible with different brand treatment equipment at the same time.

Technical advantages: own R & D center / professional research team / years of VOCs governance and monitoring application experience.

Quality advantage: good stability, core key components are imported from abroad/ Ensure the stable operation of the equipment / real-time, accurate negative pressure sampling, continuous and stable air flow / not affected by the pump pulse air flow / ensure no lag in the measurement of exhaust gas concentration / high accuracy, adopt precise control system / achieve the current higher level in the industry in terms of the quality of accessory selection and the accuracy of electronic control;

Service advantages: we always adhere to the quality priority, accessories and consumables are selected high-end brands, to ensure that the service life of the equipment is extended, reduce the amount of maintenance / matching with environmental protection treatment equipment, provide integrated high-quality after-sales service / have a professional maintenance team, 40 service outlets across the country, provide comprehensive service guarantee.

system composition

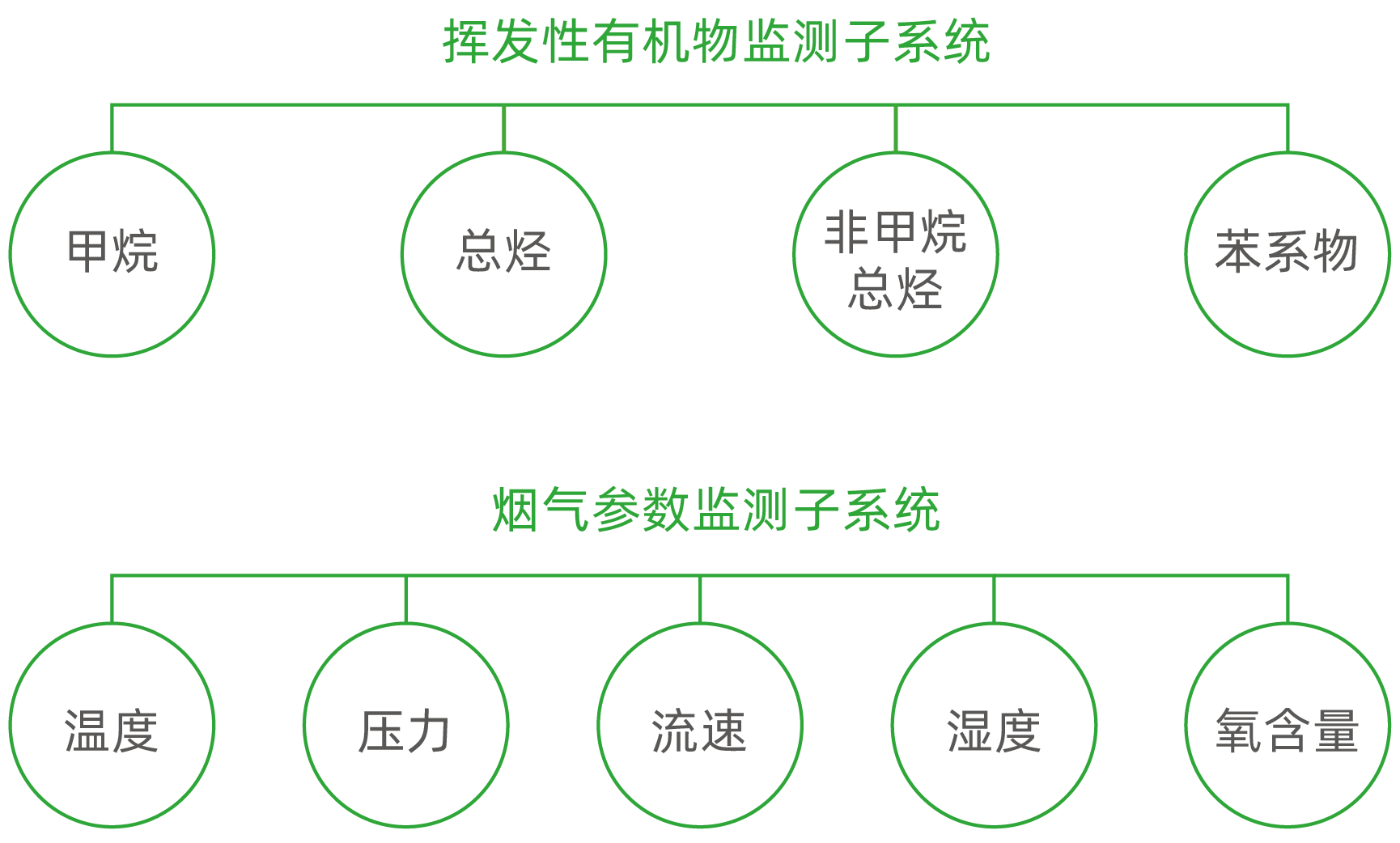

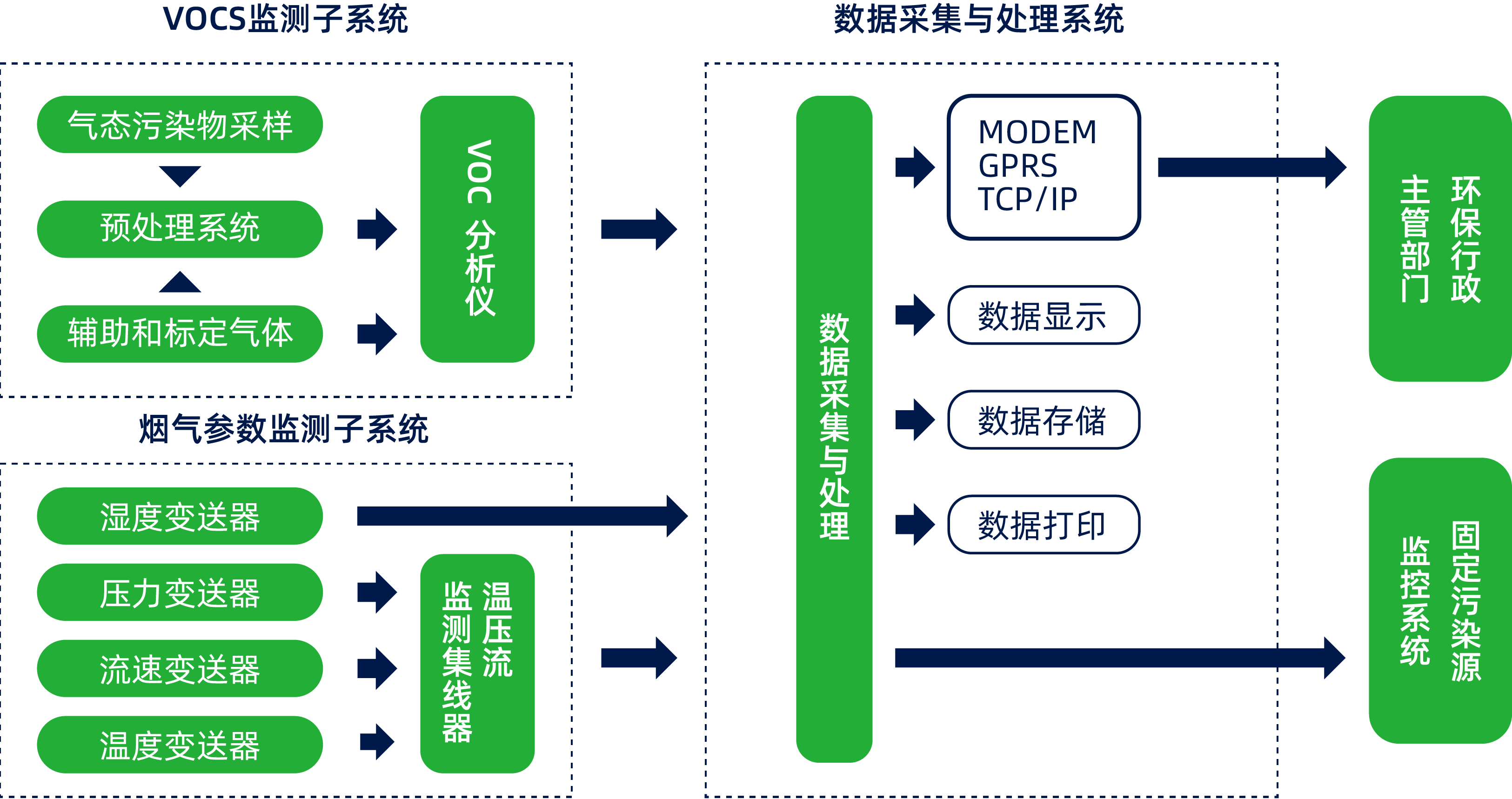

Hsj VOCs online monitoring system (CEMS continuous emission monitoring system) consists of volatile organic compounds (methane / total hydrocarbon / non methane total hydrocarbon / benzene series) monitoring subsystem, flue gas parameters (temperature, pressure, flow rate, humidity, oxygen content) monitoring subsystem, data acquisition and processing subsystem VOCs monitoring subsystem: gaseous pollutant sampling / pretreatment system / auxiliary and calibration gas / VOC analyzer

System functions

分析仪

在线除烃仪

空气发生器

工控机

氢气发生器

Full automatic sampling and injection structure design can realize on-line continuous monitoring function;

The whole process of high temperature tracing ensures the authenticity of sample gas and the accuracy of data;

The timing back blowing function ensures the smooth flow of the gas path;

The whole calibration function ensures the accuracy of sample data, and has the half calibration function, which can accurately calibrate the equipment under the condition of saving standard gas;

Automatic calibration function can significantly reduce the daily maintenance workload;

•

The 15.1-inch large LCD screen is used to display the data at a glance;

•

The professional system software has powerful functions, which can intuitively and dynamically display various detection data and trend charts, automatically calculate daily average value, monthly average value, pollution index, etc., generate various reports and save them in the system, and print them;

Multiple communication control interfaces (4-20mA, RS485, RS232, LAN) ensure timely data upload;

•

The installation process is simple and has good anti-interference ability;

•

The system can provide overrun alarm and accident alarm;

•

It has the function of conversion between ppm and Mg / M 3 units;

•

It can be equipped with a variety of data interfaces to meet the networking requirements of government agencies (serial port, Ethernet port, analog interface, etc.);

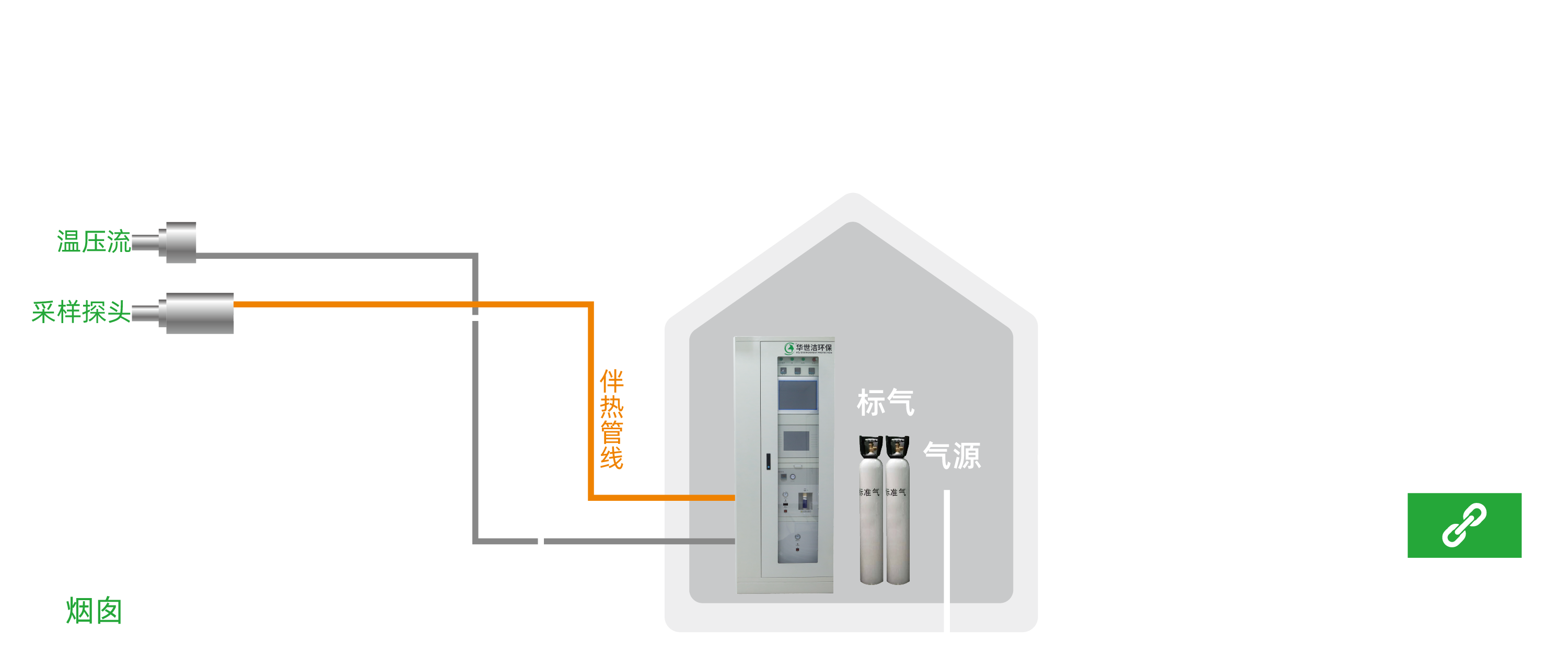

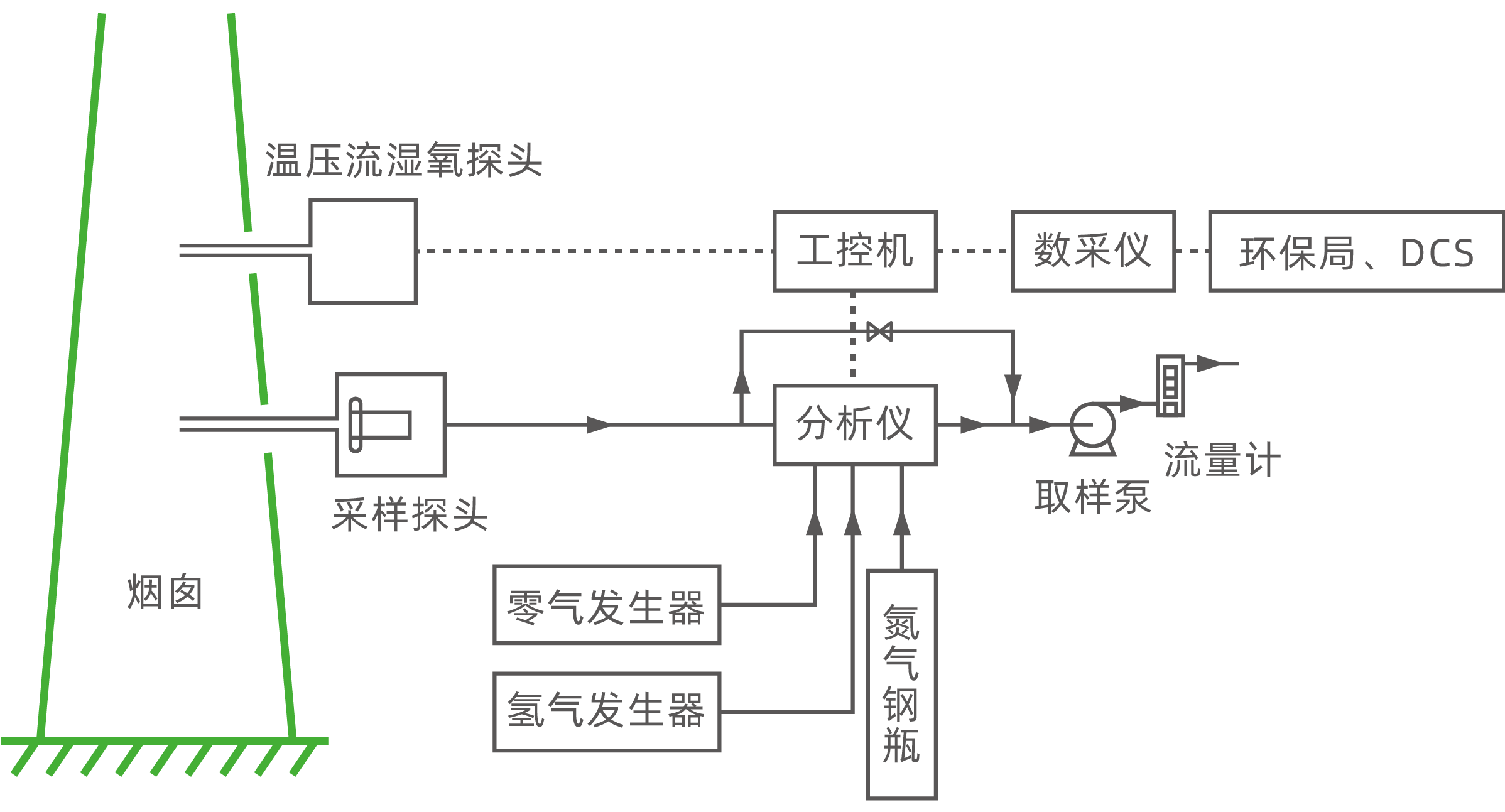

Technological process

The monitoring subsystem of volatile organic compounds (methane / total hydrocarbon / non methane total hydrocarbon / benzene series) adopts negative pressure sampling by sampling pump. The chimney exhaust gas is filtered below 5 μ m by high-temperature sampling probe, enters high-temperature heat tracing pipe, enters cabinet, and first goes through secondary fine filtration in insulation box to ensure the filtration accuracy of 2 μ M The concentration of each component (methane / total hydrocarbon / non methane total hydrocarbon / benzene series) was measured by GC-FID.

Principle of GC-FID detection

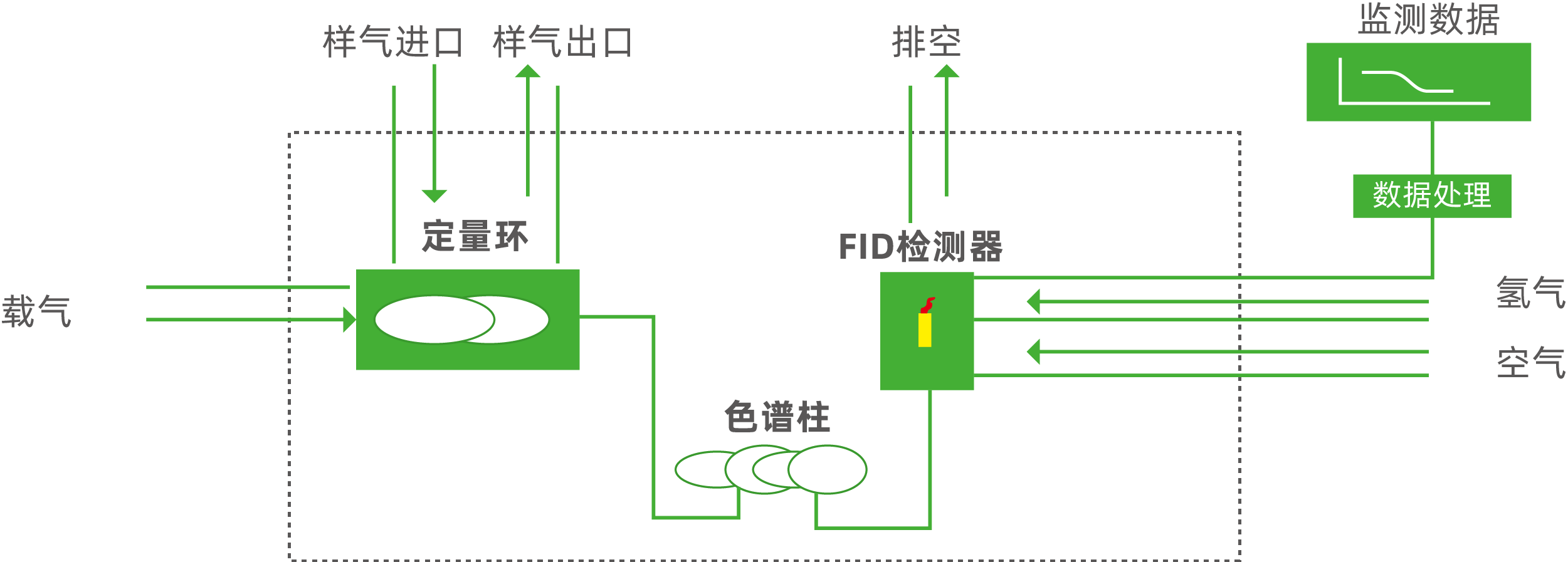

After the sample is sent to the quantitative ring, under the action of carrier gas, the sample in the quantitative ring is sent to the chromatographic column for separation, and the separated sample components are respectively introduced into the hydrogen flame ionization detector (FID) for detection, and the accurate qualitative and quantitative results can be obtained. After each analysis cycle, the system can generate a set of qualitative and quantitative data including the target components.

- • VOCs adsorption and concentration treatment

- • Thermal oxidation/catalytic oxidation

- • Adsorption and recovery of high concentration VOCs

- • Biological treatment of odor VOCs

- • Industrial dust and oil mist filtration

- • Heat recovery

- • Dehumidification

- • Indoor purification

- • VOCs Online Monitoring Platform

Nationwide service line:400 0377 123

Nationwide service line:400 0377 123