Technology Overview

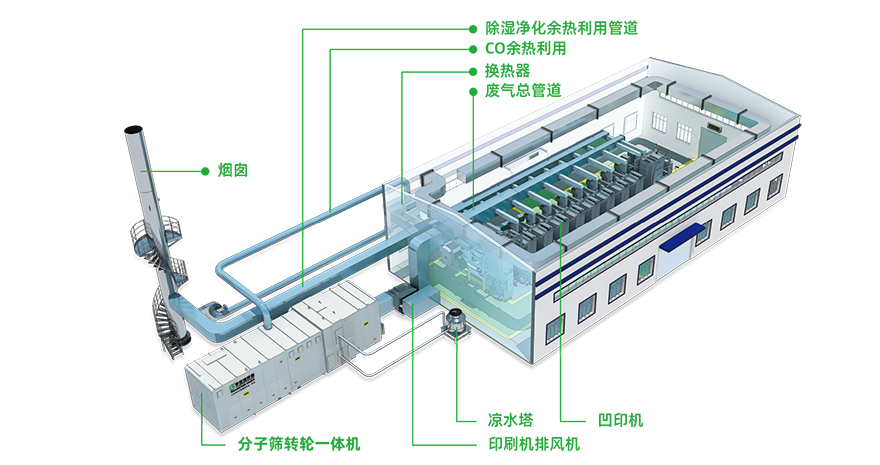

Heat recovery is a common energy saving technology of Huashijie in VOCs treatment process. It mainly uses thermal oxidation technology to heat high concentration waste gas through regenerative oxidation furnace or catalytic oxidation furnace, and make full use of the heat released by organic matter. For example, the recovered heat can be used for hot water supply in workshop, hot air supply in winter, or steam generation for utility equipment.

Technology application

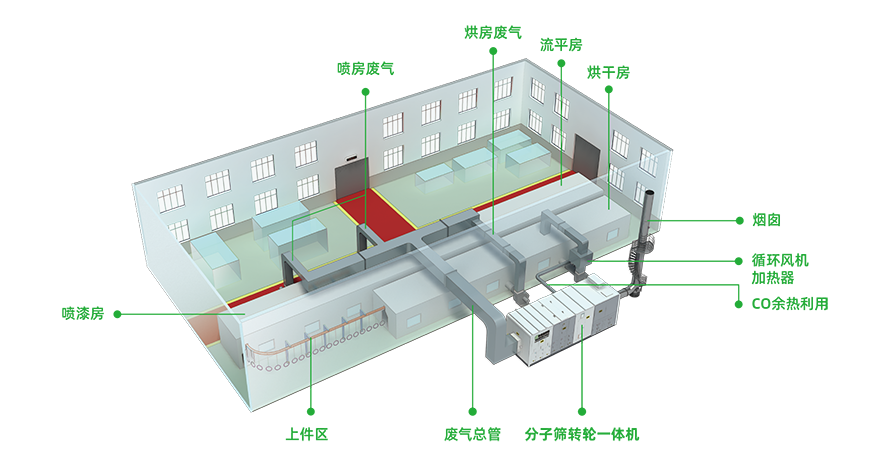

Heat recovery technology is commonly used to treat high concentration or high temperature organic waste gas. This process can be widely used in the purification of organic waste gas in electronic, container, packaging and printing, can making and other workshops. It can also be used in the supporting process design of pharmaceutical, fine chemical and other industries to achieve energy saving and emission reduction for customers, and also produce certain economic value.

Molecular sieve runner + thermal oxidation · Regenerative thermal oxidation RTO · Adsorption recovery

Technological advantages

Huashijie always takes the concept of "Care environmental protection and benefit, pursue innovation and quality” as the development concept, and creates the maximum benefit for customers while applying environmental protection.

- • VOCs adsorption and concentration treatment

- • Thermal oxidation/catalytic oxidation

- • Adsorption and recovery of high concentration VOCs

- • Biological treatment of odor VOCs

- • Industrial dust and oil mist filtration

- • Heat recovery

- • Dehumidification

- • Indoor purification

- • VOCs Online Monitoring Platform

Nationwide service line:400 0377 123

Nationwide service line:400 0377 123