Product overview

Adsorption recovery is mainly to use adsorption materials to adsorb the organic solvent in the waste gas, and then desorption to recycle the organic solvent. In organic waste gas treatment process, adsorption is one of the methods with good treatment effect and wide application. Adsorbents include activated carbon, diatomite, zeolite and so on, among which activated carbon is the most widely used. Through the adsorption system, not only the VOCs concentration in the exhaust gas can be greatly reduced, and the exhaust gas can be discharged up to the standard, but also the collected materials can be reused for production through desorption, so as to realize the material recycling and reduce the material consumption.

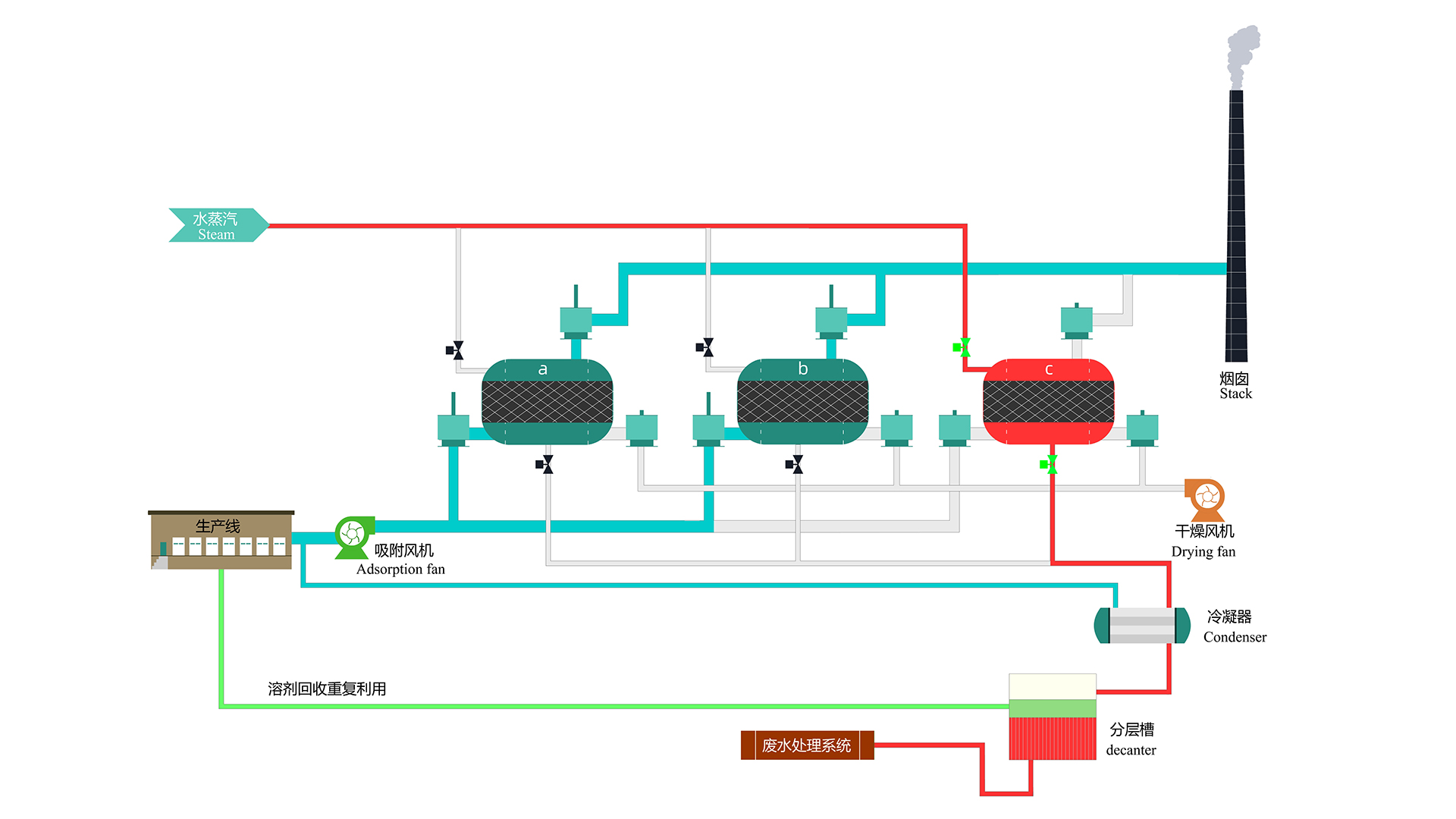

Process principle description

Adsorption: the waste gas containing VOCs passes through the adsorbent bed, VOCs are adsorbed in the microporous structure of the adsorbent, and the clean gas is discharged into the atmosphere.

Desorption: when the adsorbent is saturated, it loses its adsorption function and needs to be regenerated. The adsorbent is mainly gasified by heat source and then carried out by the carrier.

Purge: in the process of heating and gasification of adsorbate, the adsorbent is also heated correspondingly. Low temperature is conducive to adsorption, so it is necessary to reduce the temperature of adsorbent.

Product features and advantages

Advanced design concept: system integration, standardized / modular design makes the construction period more flexible / turnkey project, so that customers can leave the project to expert.

Large adsorption capacity: fast adsorption and regeneration, high adsorption efficiency and high recovery rate

Excellent and efficient operation performance: processing efficiency is above 90%.

Reliable safety performance: multiple monitoring and warning / multiple safety interlock to ensure efficient and safe operation.

Convenient and fast network interaction performance: remote control, real-time online monitoring.

Simple and efficient operation performance: modular management, programmed control, automatic operation / simple, efficient, fast, easy maintenance.

Application industry

It is suitable for pharmaceutical, film coating, painting, high strength and high modulus polyethylene (PE fiber and diaphragm), semiconductor Polymer materials, packaging printing, leather making (superfine fiber), petrochemical industry, etc.

Product overview

(Activated carbon fiber (ACF) adsorption recovery device is a device which uses activated carbon fiber (ACF) as adsorption material, through advanced, efficient, safe and reliable process, mechatronics automatic control technology to treat the organic waste gas from various industries in the production process, and fully recover the organic solvent in the industrial waste gas.

1.The adsorber can be divided into four cores, eight cores, ten cores and twelve cores.

2.Applicable conditions waste gas component: single component, with recycling value.

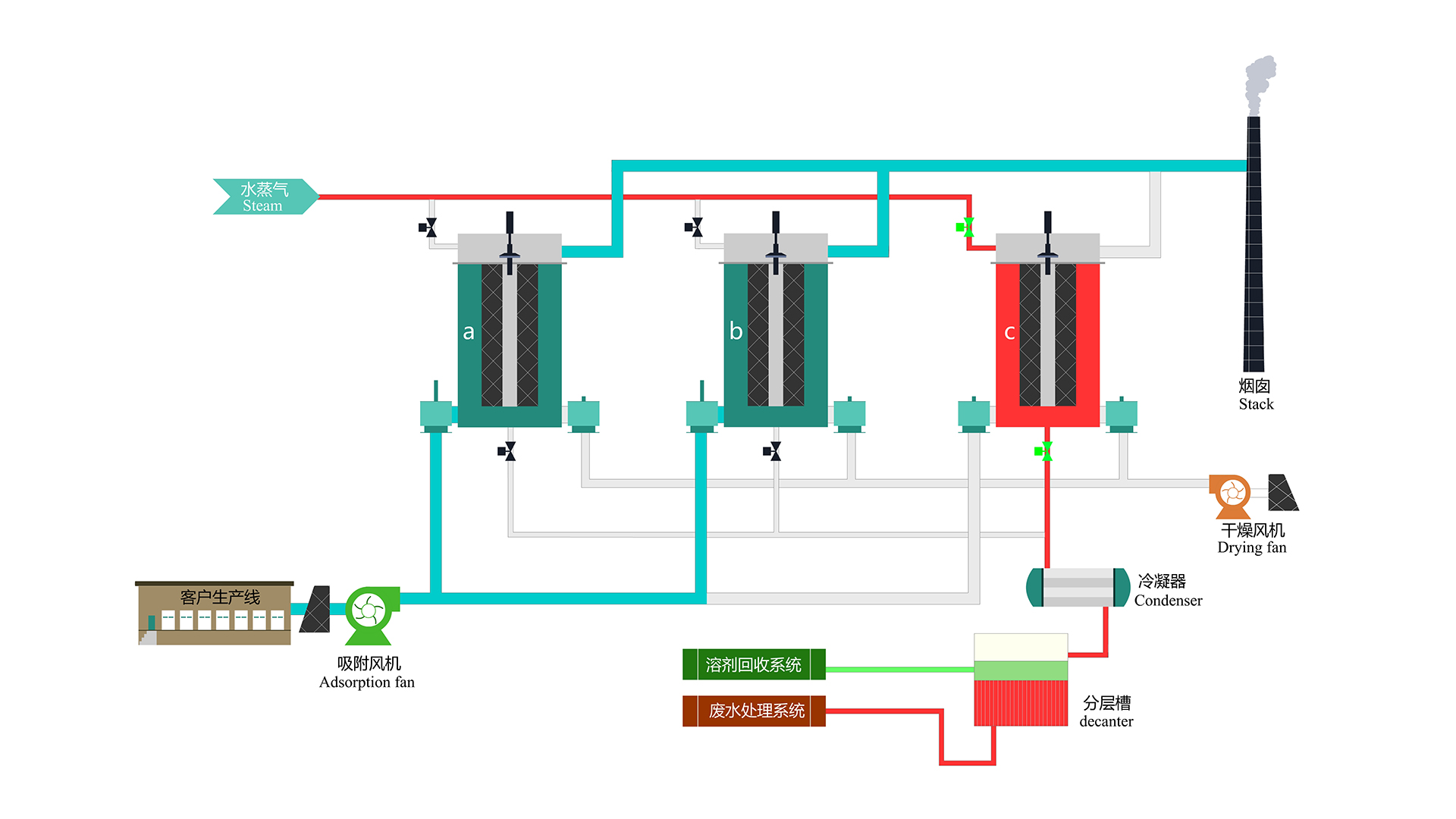

Process principle description

ACF adsorber (attached)

After the organic waste gas enters the adsorber, it circulates through the following three processes.

Adsorption process: the organic solvent in the exhaust gas is adsorbed on the surface of ACF adsorption material.

Desorption process: the organic solvent on the surface of the adsorption material is desorbed by water vapor, and then condensed and recovered.

Drying process: hot air or room temperature air is introduced to dry the adsorption material, remove the water on the surface, and reduce the temperature at the same time.

Product features and advantages

| Advanced design concept: system integration, standardized / modular design make the construction period more flexible. /Turnkey project | |

| Large adsorption capacity: fast adsorption and regeneration, high adsorption efficiency and high recovery rate | |

| Simple and efficient operation performance: modular management, programmed control, automatic operation / simple, efficient, fast, easy maintenance. |

Application industry

It is suitable for organic gas recovery from chemical, pharmaceutical, polymer materials, hydrogen peroxide, insulating materials and other industries.

Component: single component, with recycling value.

- • VOCs adsorption and concentration treatment

- • Thermal oxidation/catalytic oxidation

- • Adsorption and recovery of high concentration VOCs

- • Biological treatment of odor VOCs

- • Industrial dust and oil mist filtration

- • Heat recovery

- • Dehumidification

- • Indoor purification

- • VOCs Online Monitoring Platform

Nationwide service line:400 0377 123

Nationwide service line:400 0377 123