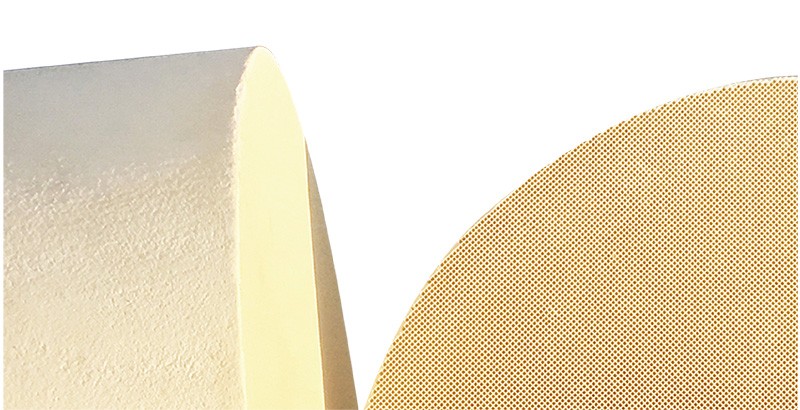

Core materials

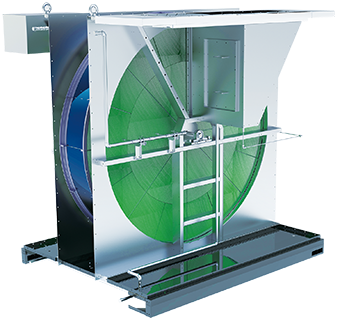

Molecular sieve adsorption concentration runner

High performance activated carbon fiber

• ACF with matching pore structure and surface properties can be selected according to different VOCs components for customization

• For different adsorbents, the adsorption capacity is increased by 30% - 100%

• Operation and maintenance costs can be reduced by 20% - 50%

Nanofiber filter materials

• The electrospinning nanofiber covering film can effectively prevent the dust from entering into the filter material and retain it on the surface of the nanofiber layer

• The filtration efficiency of dust particles with particle size above 0.3um is more than99.99%

• Increase dust capacity by more than 30%

• The initial test pressure is reduced by more than 50%

• More than 50% longer service life

• Save more than 75% compressed air

VOCs efficient catalytic oxidation materials

• VOCs high efficient catalytic oxidation material: excellent catalytic activity, high low temperature activity, low ignition temperature, strong adaptability to concentration fluctuation

• Reliable catalytic capacity, excellent removal efficiency under high concentration and high velocity conditions

• Excellent thermal stability: strong resistance to high temperaturedeterioration and stable catalyst activity

- • VOCs adsorption and concentration treatment

- • Thermal oxidation/catalytic oxidation

- • Adsorption and recovery of high concentration VOCs

- • Biological treatment of odor VOCs

- • Industrial dust and oil mist filtration

- • Heat recovery

- • Dehumidification

- • Indoor purification

- • VOCs Online Monitoring Platform

Nationwide service line:400 0377 123

Nationwide service line:400 0377 123