Service mindset

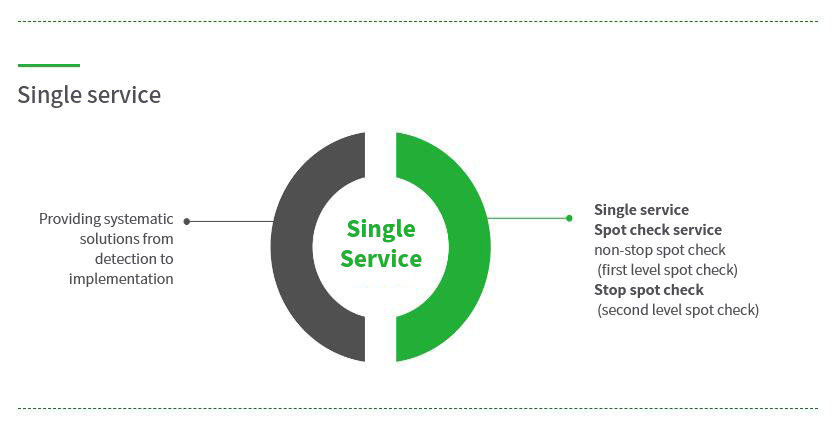

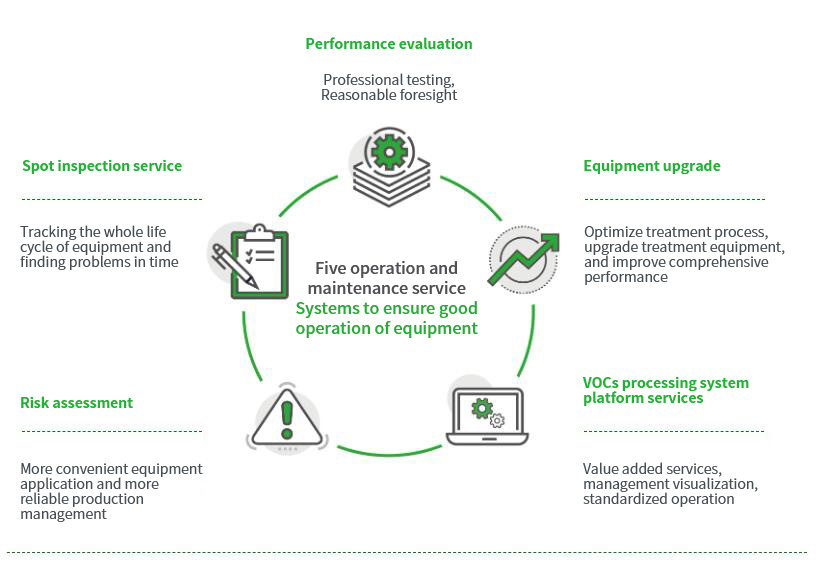

●Non-stop spot check is a relatively simple spot check service, which mainly evaluates and diagnoses the customer's running system through equipment appearance, operation data, and simple checking device and means;

●Shutdown check is a more in-depth and thorough evaluation and diagnosis of customer's VOCs treating system; Stop spot inspection not only includes all the contents of the first level spot inspection, but also requires customers to stop production to cooperate with our inspection and testing;

●In the process of spot inspection service, the maintenance service personnel will check, test and record the customer's equipment one by one according to the scheduled spot inspection service sheet. If necessary, they will also sample the molecular sieve rotor block, activated carbon material, pretreatment filter material, catalyst and typical pollutants in the equipment;

●After the completion of the spot inspection, through the analysis of the operation data and on-site sampling, the "evaluation report" is issued to analyze and evaluate the current operation status, risk points and energy consumption of the equipment, and put forward optimization suggestions.

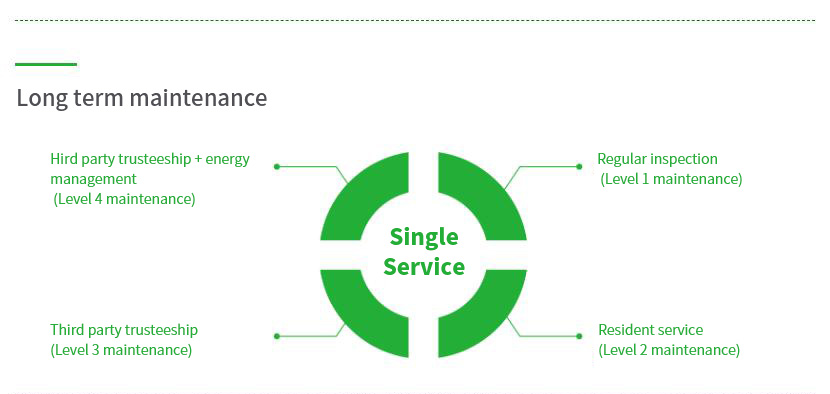

Long term maintenance

There are four different modes of long-term:

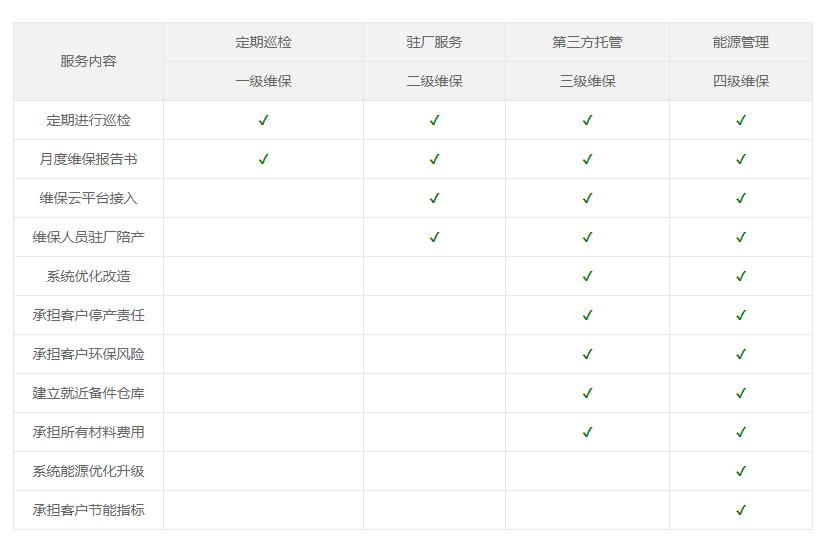

•Regular inspection and maintenance mode (first level maintenance)

Regular inspection maintenance mode, within the agreed period (usually one year); According to the timetable, cycle, frequency agreed by both parties, the maintenance personnel of Huashijie carry out on-site inspection service for the customer's VOCs management system or a specified equipment, such as molecular sieve rotor.

The items of spot inspection contents are also clearly stipulated in the maintenance contract signed by both parties. At the appointed time, the company's maintenance personnel will carry the spot check service confirmation sheet to conduct on-site service for customers. After the spot check, the company will issue the maintenance report to the customer according to the results and data taking by service personnel. The maintenance report mainly includes the following contents:

①According to the spot inspection data, the operation status of the system and equipment is evaluated, the existing problems and risk points of the equipment are pointed out, and the suggestions for optimization and rectification are put forward; If there is a sampling in the field that is brought back to the laboratory for testing or analysis, separate analysis data results shall be attached;

②According to the current operation conditions, the consumables and spare parts plan for the next operation cycle shall be formulated for the customer, and the customer shall purchase them. Regular inspection mode does not include the purchase and replacement cost of consumables and spare parts, therefore it will be a separate quotation;

③Give written reply to the alarm records of the system or the problems in operation raised by the customer in this patrol inspection cycl;

④Provide energy consumption statistics of system or equipment, and provide the energy consumption evaluation.

•Resident service mode (secondary maintenance)

The resident service mode is within the agreed period (usually one year); according to the scale and actual demand of customer's VOCs management system,

Huashijie sends personnel to the customer site and sign in on time every day according to customer requirements and maintenance agreement.

The main responsibilities of the company personnel in the factory include but are not limited to:

① Control the start and stop of VOCs management system and equipment according to customer's production plan every day;

② Daily routine inspection of customer system equipment, and record the operation status of the equipment;

③In case of equipment failure alarm or other abnormal conditions, timely solve them on site to ensure normal production of customers; For the failure that cannot be eliminated in the first time, timely communicate with the company's maintenance personnel, and make the response plan as soon as possible; For all kinds of faults occurred in the current month, the analysis report and follow-up solutions are formed and submitted to customers in the current month as part of the monthly maintenance report;

④According to the operation and maintenance situation of the current month, make the purchasing plan of consumables and spare parts for the next month, and submit it to the customer as the attachment of the monthly maintenance report, which will be purchased by the customer;

⑤Authorize the access for customers on the maintenance management platform of Huashijie. Customers can understand the real-time operation and periodic operation data of the equipment through the wireless network; Download the inspection record and monthly maintenance report.

•Third party trusteeship mode (level three maintenance)

The third-party trusteeship mode is based on the resident service mode, which includes all the consumables, spare parts and the spot inspection, equipment operation, repair and maintenance costs required to ensure the normal operation of VOCs management system in the maintenance contract.

In addition to the above expenses, the third-party trusteeship mode also bears the following responsibilities:

① ①Be responsible for the emission indicators and treatment effect of environmental protection equipment, and bear the responsibility caused by excessive emission of equipment;

②②Responsible for the continuous and stable operation of environmental protection equipment and customer's production line, agree with the customers on the number and time of abnormal shutdown in the whole year, and undertake the responsibility of abnormal shutdown beyond the agreed time;

③ Be responsible for the safety of environmental protection equipment, and undertake the safety responsibility during the maintenance period;

④Be responsible for the handover status of environmental protection equipment. When the maintenance period is over, promise to the customer that the performance indicators of the equipment when it is returned will not be lower than the status when it is received.

System operation and maintenance

- • VOCs adsorption and concentration treatment

- • Thermal oxidation/catalytic oxidation

- • Adsorption and recovery of high concentration VOCs

- • Biological treatment of odor VOCs

- • Industrial dust and oil mist filtration

- • Heat recovery

- • Dehumidification

- • Indoor purification

- • VOCs Online Monitoring Platform

Nationwide service line:400 0377 123

Nationwide service line:400 0377 123